In a groundbreaking revelation that defies conventional scientific wisdom, a team of scientists from Sandia National Laboratories and Texas A&M University has borne witness to a mesmerizing phenomenon – pieces of metal cracking and then miraculously fusing back together without any human intervention. This extraordinary discovery has the potential to herald an engineering revolution, transforming the way we perceive self-healing engines, bridges, and airplanes. Imagine a future where wear and tear-induced damage can be effortlessly reversed, making our machines safer, more durable, and longer-lasting.

The team’s remarkable findings, revealed in the prestigious journal Nature, have left researchers astounded. Sandia materials scientist, Brad Boyce, expressed his amazement, describing the experience as “absolutely stunning to watch first-hand.” He further explained that metals possess their intrinsic, natural ability to heal themselves, at least when it comes to nanoscale fatigue damage.

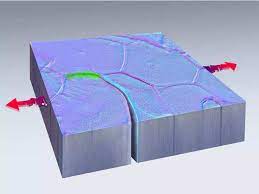

Fatigue damage, which leads to the gradual deterioration and eventual failure of machines, occurs when repeated stress or motion causes tiny microscopic cracks to form. Over time, these seemingly minuscule fractures grow and spread, culminating in catastrophic failures. These failures have far-reaching consequences, from costly replacements and downtime to potential injuries or even loss of life, resulting in a staggering economic impact on the United States, amounting to hundreds of billions of dollars annually.

Until now, self-healing materials have mainly been limited to plastics, leaving the idea of self-healing metals confined to the realm of science fiction. The notion of cracks in metals healing themselves, contrary to expectations, challenges fundamental equations used to describe crack growth. However, in 2013, Michael Demkowicz, a professor at Texas A&M and then an assistant professor at MIT, introduced a groundbreaking theory. Based on computer simulations, he proposed that, under certain conditions, metals could weld shut cracks caused by wear and tear.

The serendipitous confirmation of Demkowicz’s theory came during an experiment at the Center for Integrated Nanotechnologies. Researchers were attempting to study how cracks spread in nanoscale platinum using an advanced electron microscope technique. Surprisingly, after about 40 minutes, the damage reversed course, with one end of the crack miraculously fusing back together. It was as if the crack was retracing its steps, leaving no evidence of its former existence. Over time, the crack regrew in a different direction, a revelation that has been hailed as an “unprecedented insight.”

While much remains unknown about the self-healing process, including its practical applications in manufacturing settings, this discovery marks a significant stride in materials science. Boyce hopes that these findings will encourage researchers to explore the unexpected capabilities of materials under specific circumstances.

As we ponder the boundless potential of this self-healing phenomenon, we envision a future where our structures become resilient, enduring, and in harmony with nature. This newfound understanding opens a world of possibilities, and researchers eagerly await the extensive research that will undoubtedly propel us further into the frontier of materials science.

Sandia National Laboratories, a formidable multi-mission laboratory operated by National Technology and Engineering Solutions of Sandia LLC, a wholly-owned subsidiary of Honeywell International Inc., plays a crucial role in nuclear deterrence, global security, defense, energy technologies, and economic competitiveness. With main facilities in Albuquerque, New Mexico, and Livermore, California, Sandia Labs is at the forefront of innovation, shaping the future with pioneering research and development efforts.

bhalakatha

prayas

mind plugin

#bhalakatha #prayas #MindPlugin